Na-ion battery

Fundamentals on Sodium-ion battery

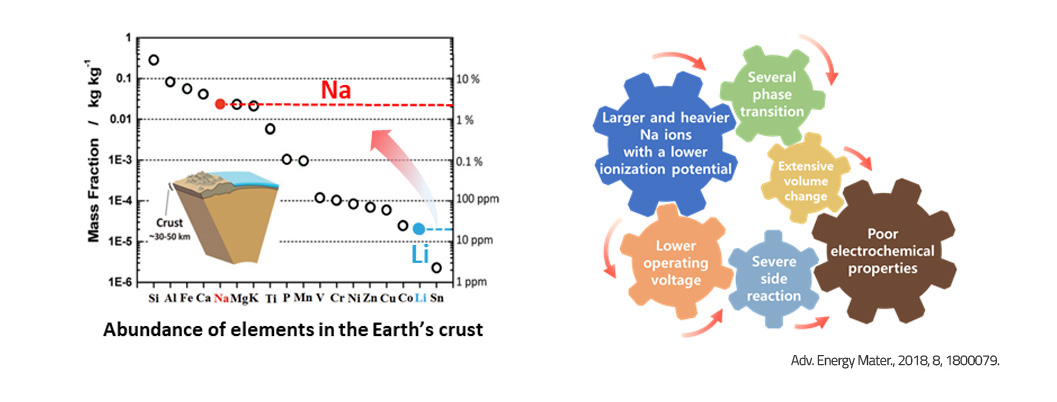

Sodium-ion Batteries (SIBs), one of the alternative candidates to Lithium-ion batteries (LIBs), have gained in much attention over recent years because of the abundance

in the earth’s crust and much lower cost of the raw materials compared with LIBs. In spite of such efforts, however, lower energy density of materials for SIBs is remain

a hurdle to be overcame.

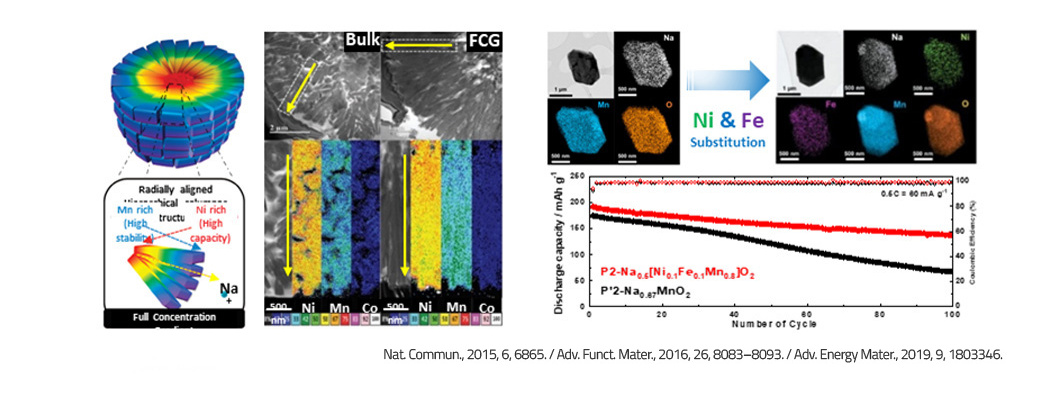

Cathode Materials – new concept/design

In order to improve the electrochemical activity and structural stability, our researches are focused on develop or design a new concept cathode materials.

These works mark an important step further in the design of functional cathode materials led to excellent electrochemical and mechanical properties.

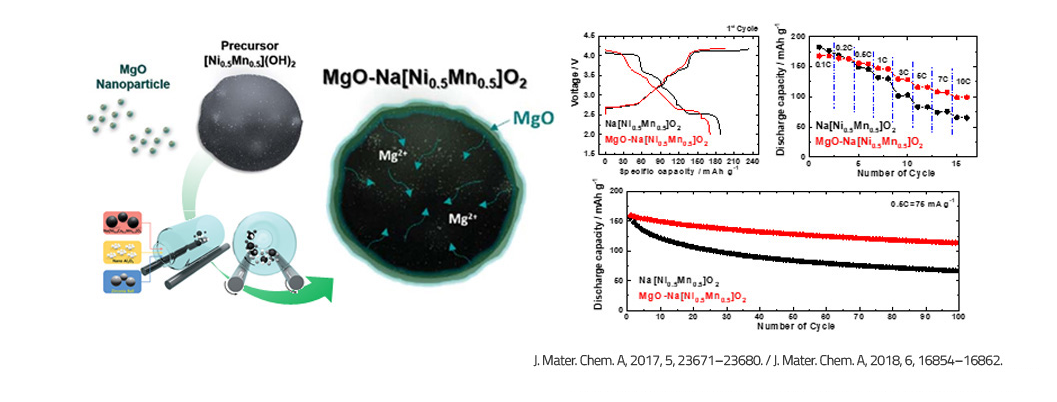

Cathode Materials – Coating &l Doping method

The surface coating and doping methods are proposed to modify electrochemical and structural properties of cathode material. These simple and cost-effective

approaches are helpful for understanding the SIBs system and further developing commercial SIBs.

Li-S battery

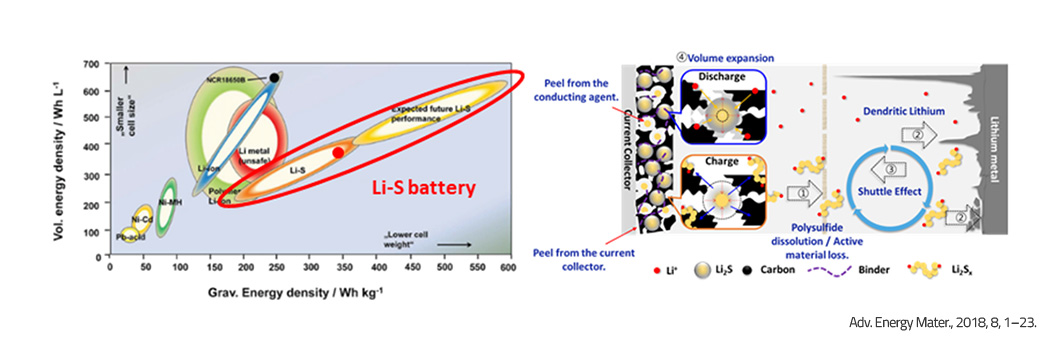

Fundamentals on Lithium-Sulfur battery

Li-S batteries are among the more auspicious candidates as next-generation batteries, owing to the abundance and inexpensive cost of raw sulfur, environmental benignity, theoretical capacity of 1675 mAh g-1 for sulfur cathodes, and theoretical energy density of 2500 Wh kg-1. Yet, in spite of their benefits, Li-S batteries have not been successfully commercialized so far, since they suffer from several problems: 1) Li-sulfides dissolution and their shuttle reactions that avoid full oxidation of the Li-sulfides to sulfur in the cathodes, 2) volatility of the conventional ether-based electrolyte solutions, and 3) only a partial utilization of sulfur at the cathodes due to the low sulfur conductivity of 5 x 10-30 S cm-1.

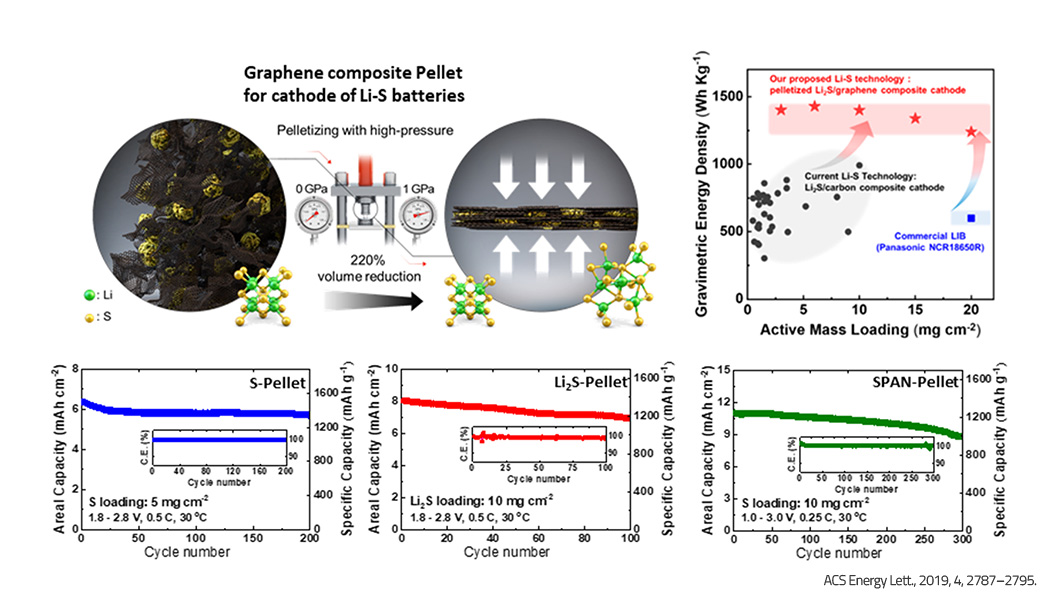

New-type cathode structure for high performances of Li-S battery :Nano-compacted Li2S/graphene composite cathode

A mixture of graphene and Li2S is pelletized by a volume reduction of 220% to synthesize a high energy density cathode for Li–S batteries. The pelletized Li2S/graphene cathode represents a breakthrough in Li−S battery technology, providing the high energy and high-power density promised by the technology, while ensuring the required battery lifetime. Which plots the gravimetric energy density against the active mass loading for the Li2S/carbon batteries reported in the literature and for the state-of-the-art commercial Li-ion battery. (Panasonic NCR18650B) At present, the cathode fabrication technology is applied to Sulfur and S-PAN as well as Li2S batteries.

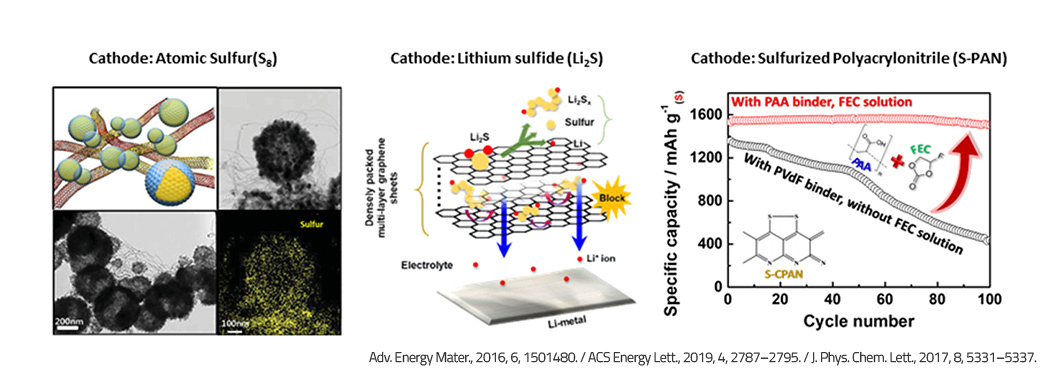

Various type of sulfur cathode materials fabrication

With sulfur, Li2S and S-PAN, we are doing research on cathode materials of Li-S battery, and we are presenting achievements in all fields. Each positive electrode has different characteristics, and the development of Li-S battery, one of the next generation batteries, requires even development and comparative analysis in each cathode material.

Li-air battery

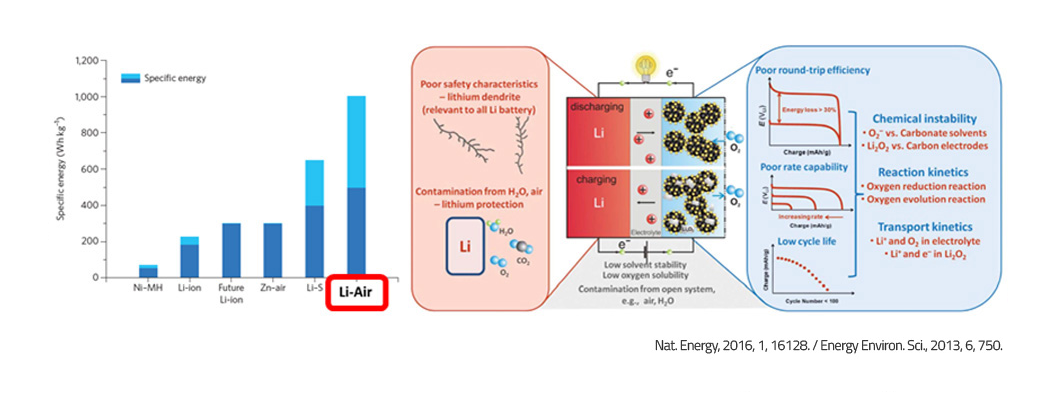

Fundamentals on Lithium air battery

Rechargeable non-aqueous lithium oxygen (Li-O2) batteries have attracted worldwide research attention due to high theoretical specific energy density (more than

1000 Wh kg-1). However, poor cycle life and low energy efficiency, derived from electrical insulating nature of discharge product and irreversible side reactions, limit the

practical application of Li-O2 batteries.

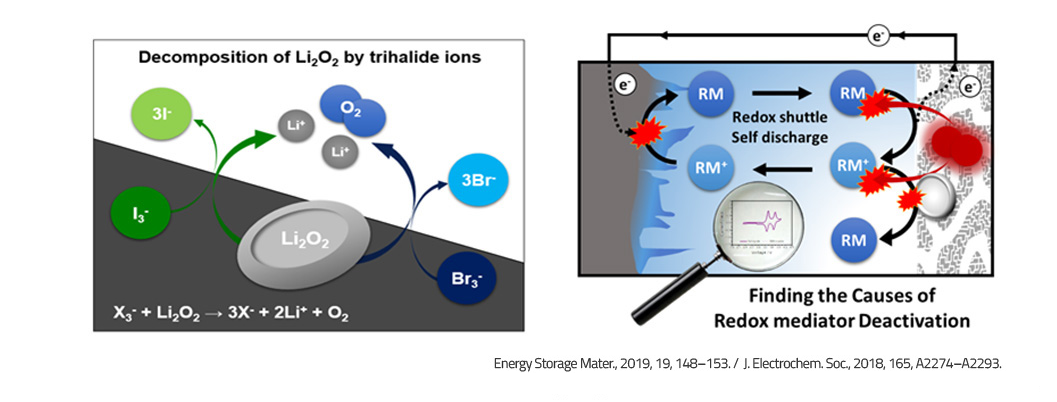

Redox mediator

In order to facilitate the formation and decomposition of Li2O2 and increase the energy efficiency, our researches are focused on redox mediators (RMs) which is the

soluble catalyst in Li-O2 batteries. We are developing the new RMs, making strategies to use the RMs more effectively, and revealing the problems of RMs.

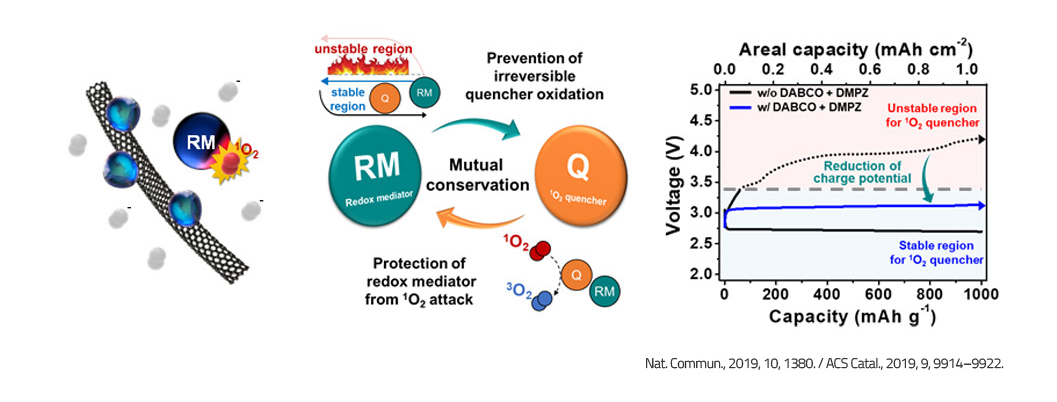

Singlet oxygen chemistry

Our researches are focused on alleviating the irreversible side reactions in Li-O2 batteries. As it is demonstrated that singlet oxygen (1O2) revealed as main cause of

side reactions in Li-O2 batteries, we are also focusing on the singlet oxygen chemistry to improve the stability of the Li-O2 batteries.

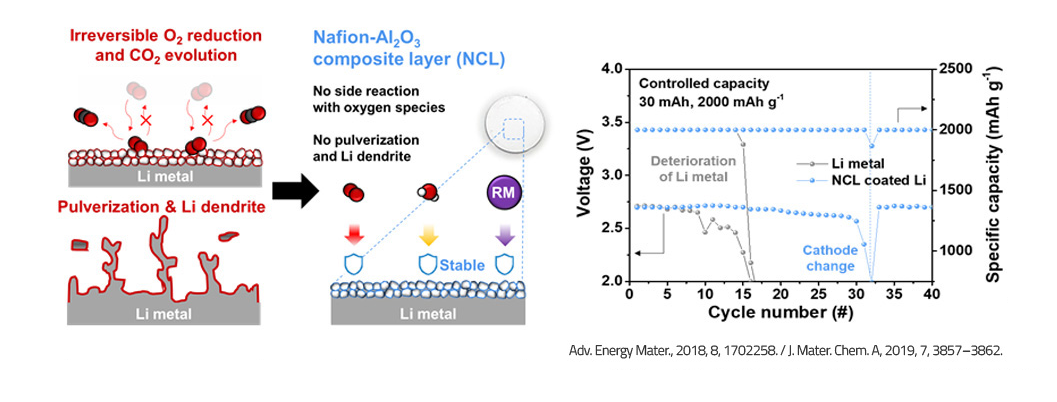

Lithium metal protection

For the Next-generation batteries using lithium metal as anode material, controlling the lithium metal, which is very reactive material, is important issue.

We are developing the stable lithium metal protective layer to suppress the lithium dendrite and side reactions on the surface of lithium.