Fundamentals on Lithium metal battery

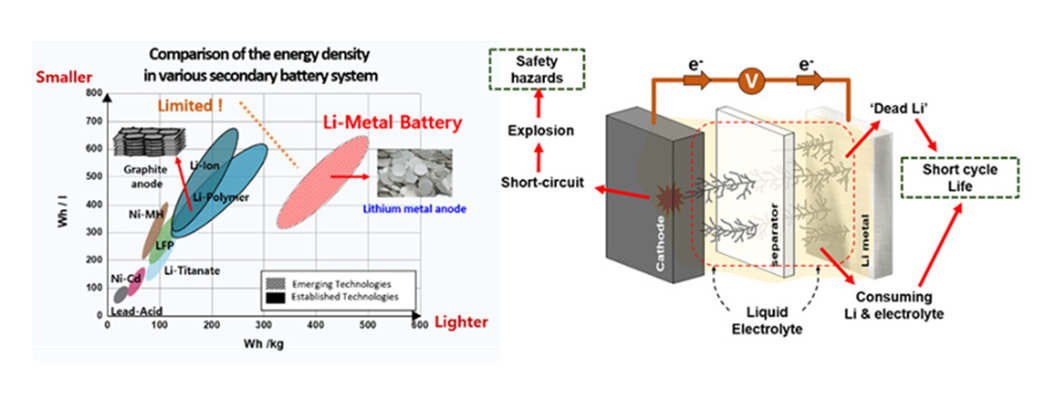

The rechargeable battery using metallic Li as an anode is strongly considered to be one of the most promising energy storage technology because of its high-

energy density. However, the practical application has been plagued by the issue of inferior electrochemical cycling stability and safety hazard due to the

thermodynamic instability of Li metal anode.

External pressure modulated LMBs

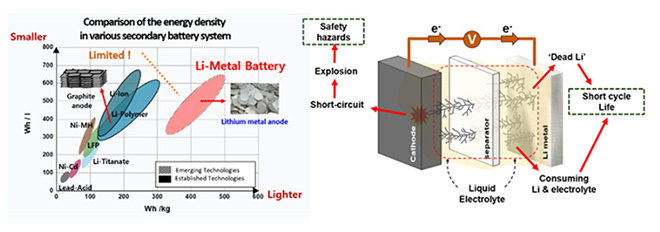

The reason for the inferior electrochemical cycle stability of lithium metal batteries is that Li+ is not deposited uniformly. Applying external pressure enables

denser uniform Li deposition on the Li anode, and also suppresses the formation of microcracks in the Ni-rich cathode from the stress applied on the cathode

during cycling. Therefore, the introduction of external pressure is an important key point in improving the lifespan of lithium metal batteries.

Electrolyte control

During the cycling of Lithium metal batteries, Lithium intercalation/de-intercalation and plating/stripping are greatly affected by the interphase layer (CEI, SEI)

formed between electrodes and electrolyte. By changing the composition of the electrolyte, the components of interphase layer can be designed, and side

reaction between the electrodes and electrolyte can be reduced. This can improve the morphology of Lithium plating and mitigate the formation of microcrack

and impurity layers on the cathode.

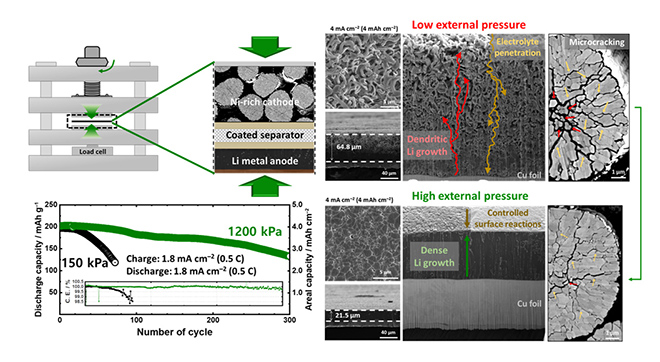

High Energy Pouch-type LMBs

Lithium metal is a promising anode, due to a high capacity of 3,860 mAh g-1 and a low potential of -3.040 V (vs. SHE). Pouch-type cells are essential to realize

long-life, high-energy-density lithium metal batteries. To realize high energy density, our lab established the above strategies based on high loading Ni-rich

cathode. First, the Introduction of external pressure modulated cells. Second, Electrolyte control. Third, Staking cell.

Through three strategies, research is focused on the development of long-life lithium metal batteries with high energy densities of 400-500 Wh kg-1.