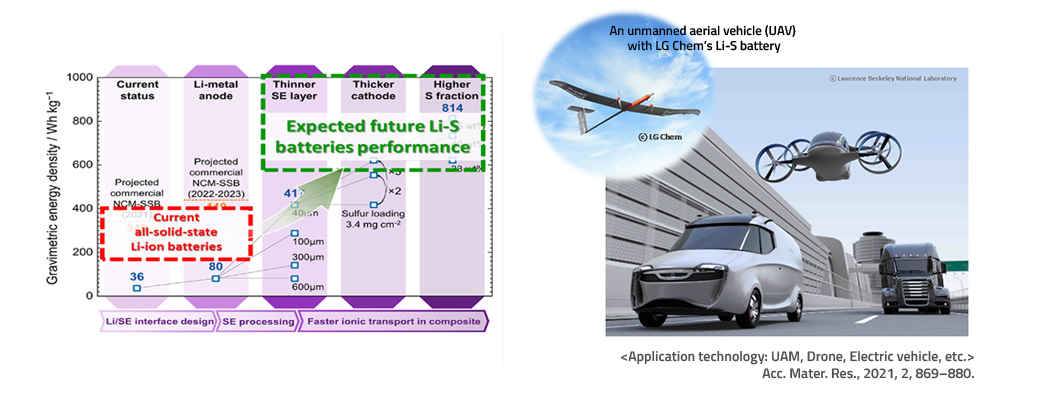

Fundamentals on All-solid-state lithium-sulfur batteries

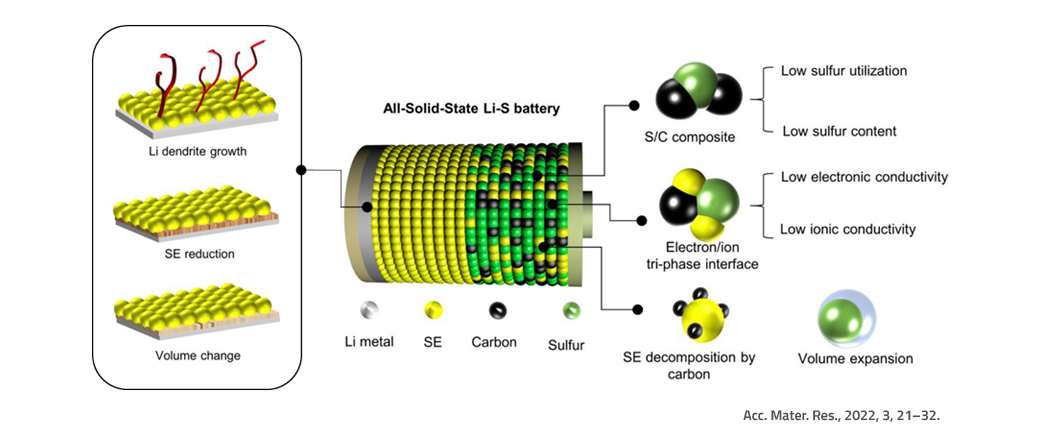

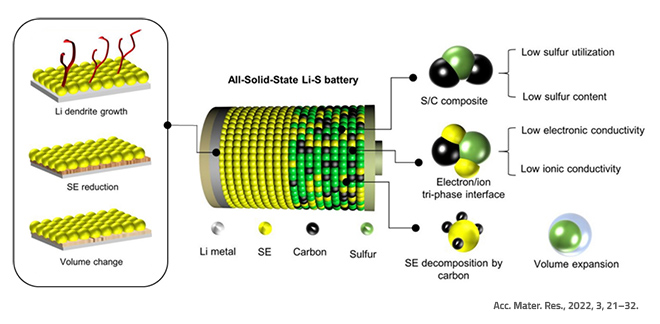

Lithium Sulfur (Li-S) batteries are promising next-generation battery candidates, due to the inexpensive cost, and superior theoretical energy density (2500

Wh kg–1). But, the dissolution of lithium polysulfide (LiPS) intermediates undermines the cycle life of liquid electrolyte-based Li-S batteries. A potential

solution is to replace liquid electrolytes with solid electrolytes (SEs) in Li-S batteries. By utilizing SEs that do not dissolve LiPS intermediates, all-solid-state

Li-S batteries (ASSLSBs) can provide significant advantages compared to liquid electrolyte-based Li–S batteries.

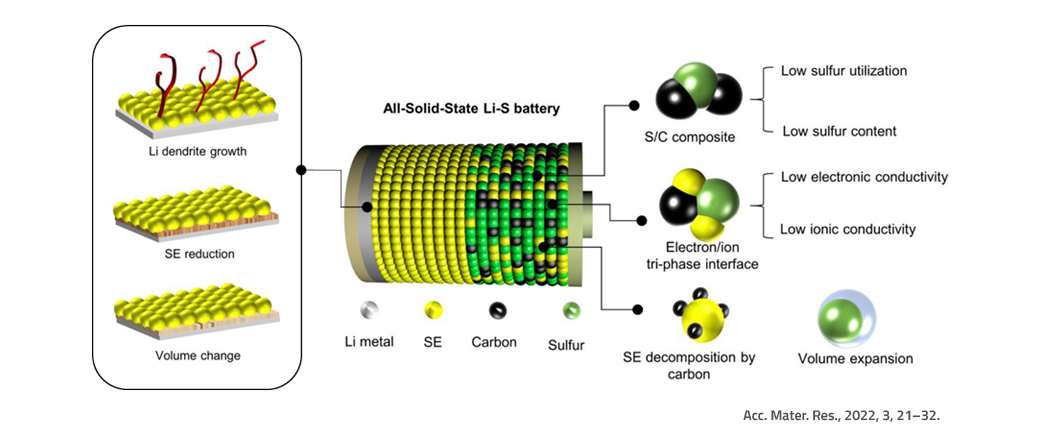

However, in the cathode of ASSLSBs, the very low electrical and ionic conductivity of sulfur leads to limited sulfur utilization and content, thereby restricting

the increase in energy density. Moreover, there are problems of volume expansion and solid electrolyte decomposition caused by excessive carbon, and

the utilization of lithium metal as an anode faces challenges. Therefore, it is crucial to develop innovative materials and electrode designs that effectively

address these challenges in order to unlock the full potential of ASSLSBs.

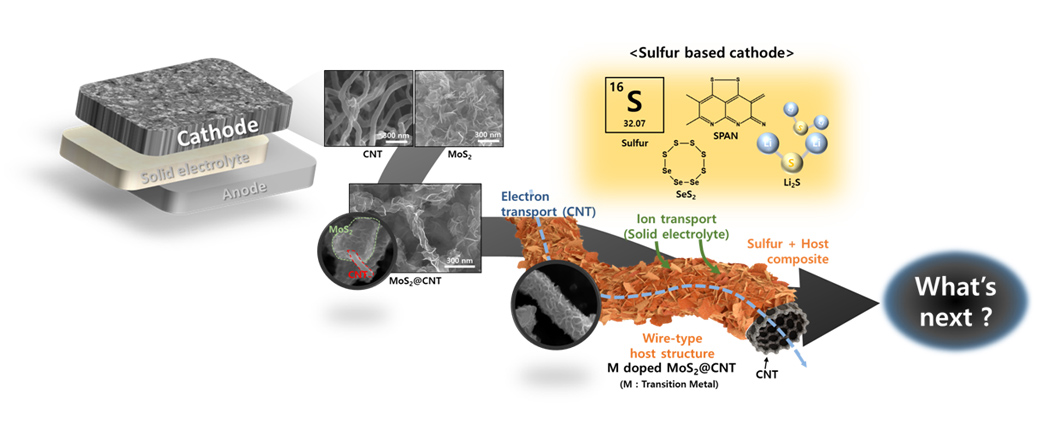

Designing a host structure

To electrochemically activate sulfur in ASSLSBs, it is necessary for the sulfur cathode to maintain close contact with both the solid electrolyte and carbon

species, thus ensuring simultaneous ion and electron transportation. We are developing an ion/electron-dual-conductive host material that can contain

a large amount of sulfur and effectively transfer electrons and ions, and identifying suitable sulfur compounds for ASSLSBs, with the ultimate objective of

developing a material with high sulfur content and loading level.

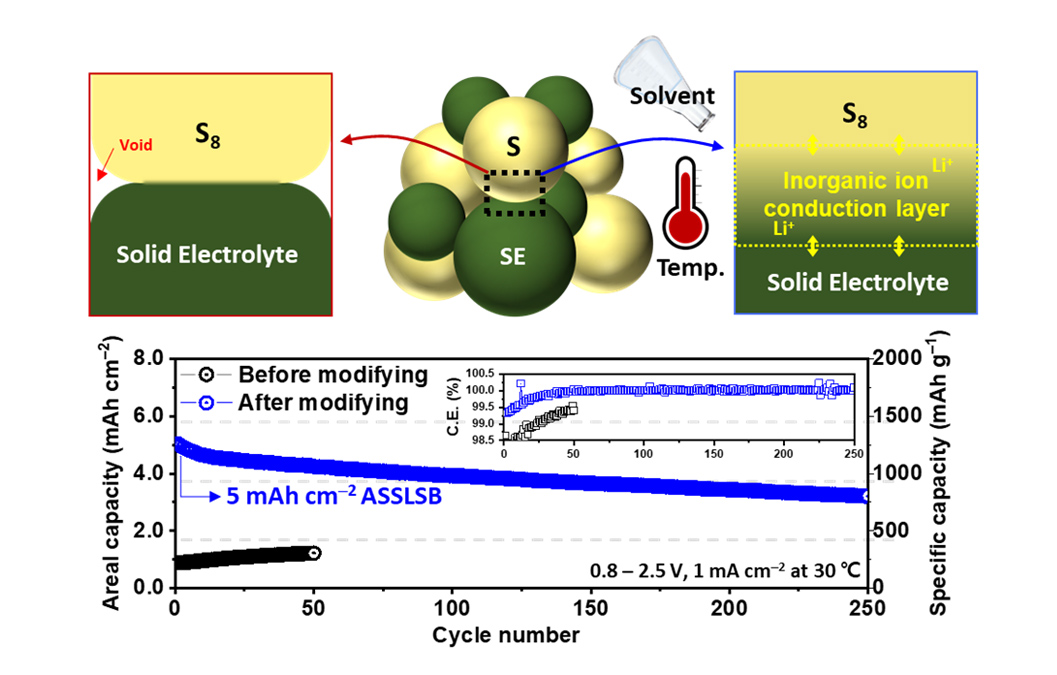

S-Solid electrolyte Interface Engineering

The stability of the interface between the SEs and sulfur is crucial for the effective exchange of lithium ions between the two materials. In ASSLSBS, both

sulfur and sulfide-based SEs possess -S end bond in their crystal structures. Therefore, they can easily form a composite material at the interface which

facilitates lithium-ion conduction. Through this reaction, an inorganic ion conducting layer between the SEs and sulfur can be formed to maximize the solid-

solid contact and stabilize the interface.

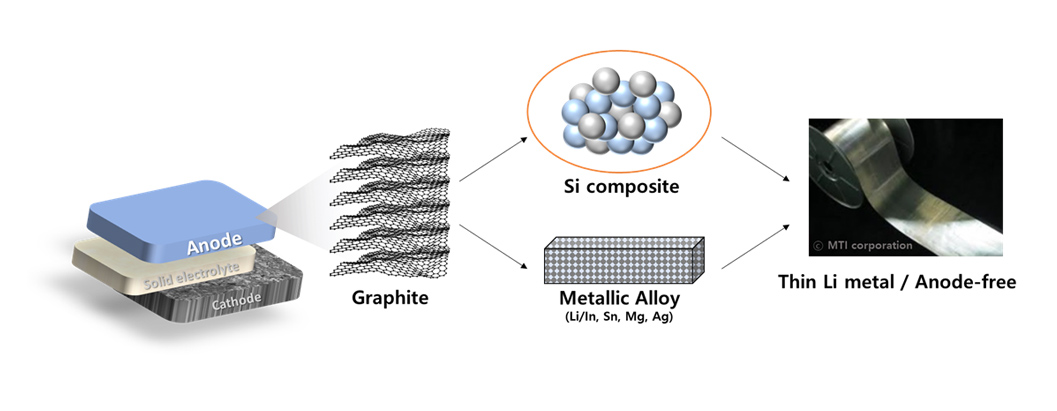

Anode materials for high-energy ASSLSBs

Utilizing thin lithium (Li) metal and an anode-free design is the ultimate goal for achieving high energy density in ASSLSBs, but it currently faces significant

challenges. Therefore, a step-by-step approach is necessary, considering different anode materials such as graphite, silicon, and metallic alloy, with the

ultimate goal of transitioning to thin Li metal and anode-free. These developments are expected to have positive impacts on energy density, safety, and life

extension.

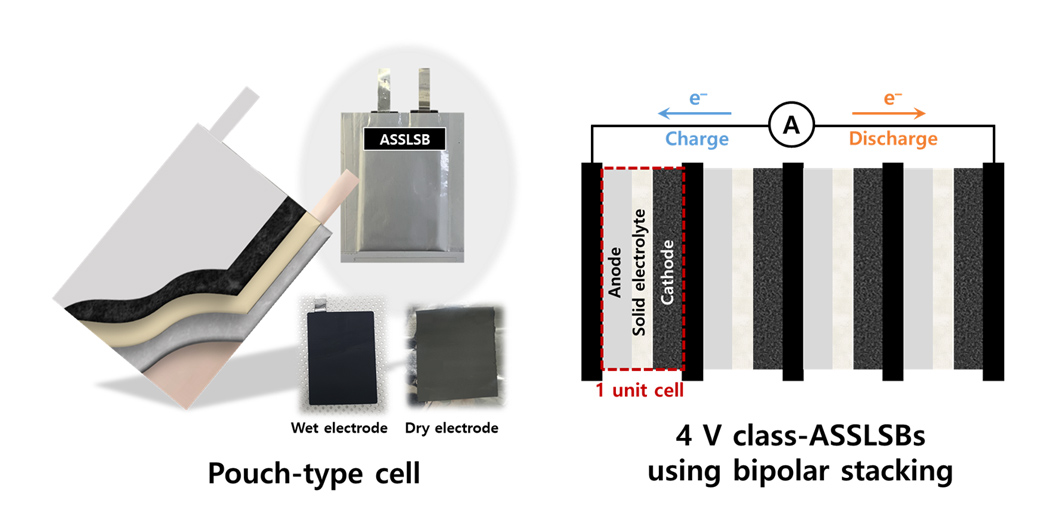

Interface Engineering

In ASSLSBs research, the fabrication of pouch-type cells is essential to ultimately achieve high energy density and large capacity. The research will involve

optimizing pouch-type cells by integrating the developed materials and technologies, with a particular focus on maximizing volumetric energy density and

increasing operating voltage through the application of bipolar stacking.