Fundamentals on All-Solid-State Batteries

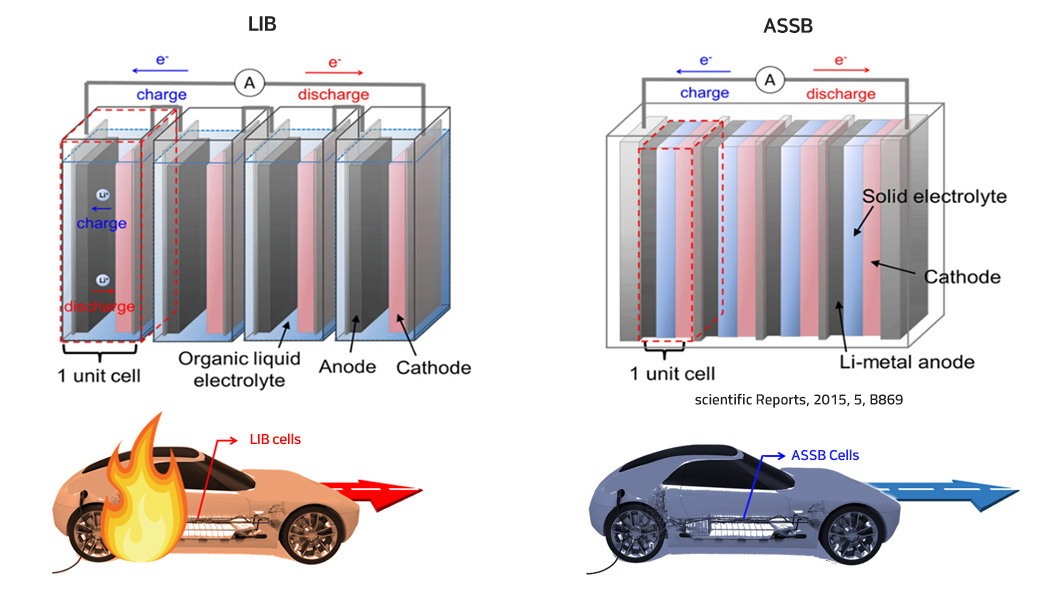

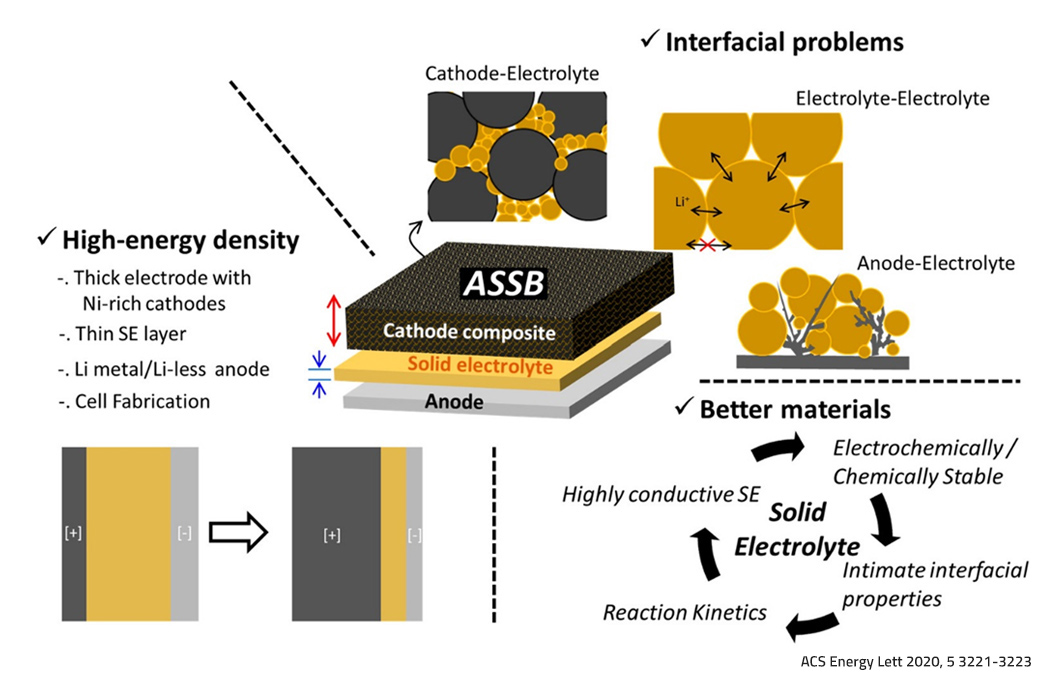

All-Solid-State Battery is a promising next-generation battery, ensuring safety and high energy density from its inflammable characteristic and bi-polar

stacking. The Li-ion battery using liquid electrolytes contains safety hazards due to its volatile and flammable characteristics. In contrast, solid electrolytes are

nonvolatile and nonflammable. Therefore, All-Solid-State Battery guarantees safety. For this safe battery to be desired by everyone, the All-Solid-State

battery should have significant improvement.

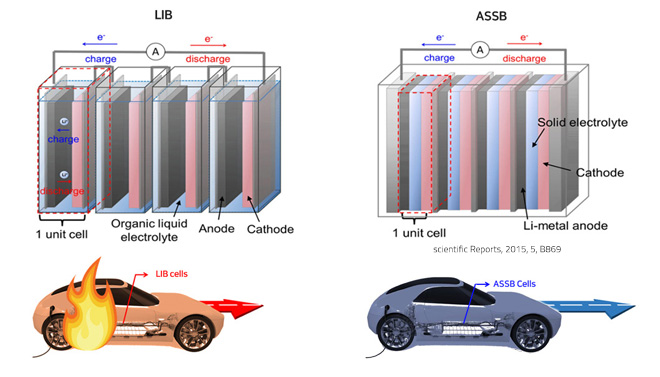

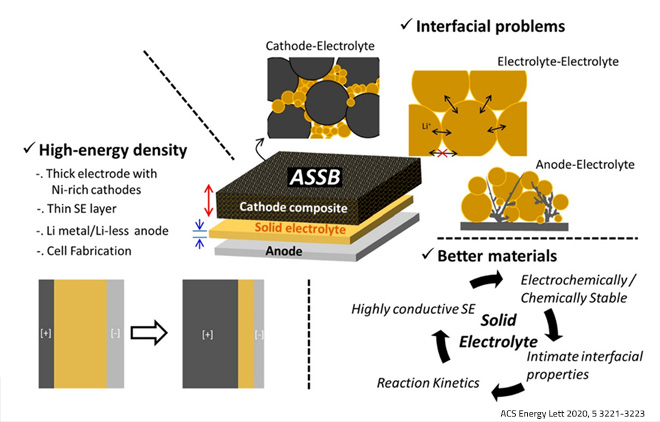

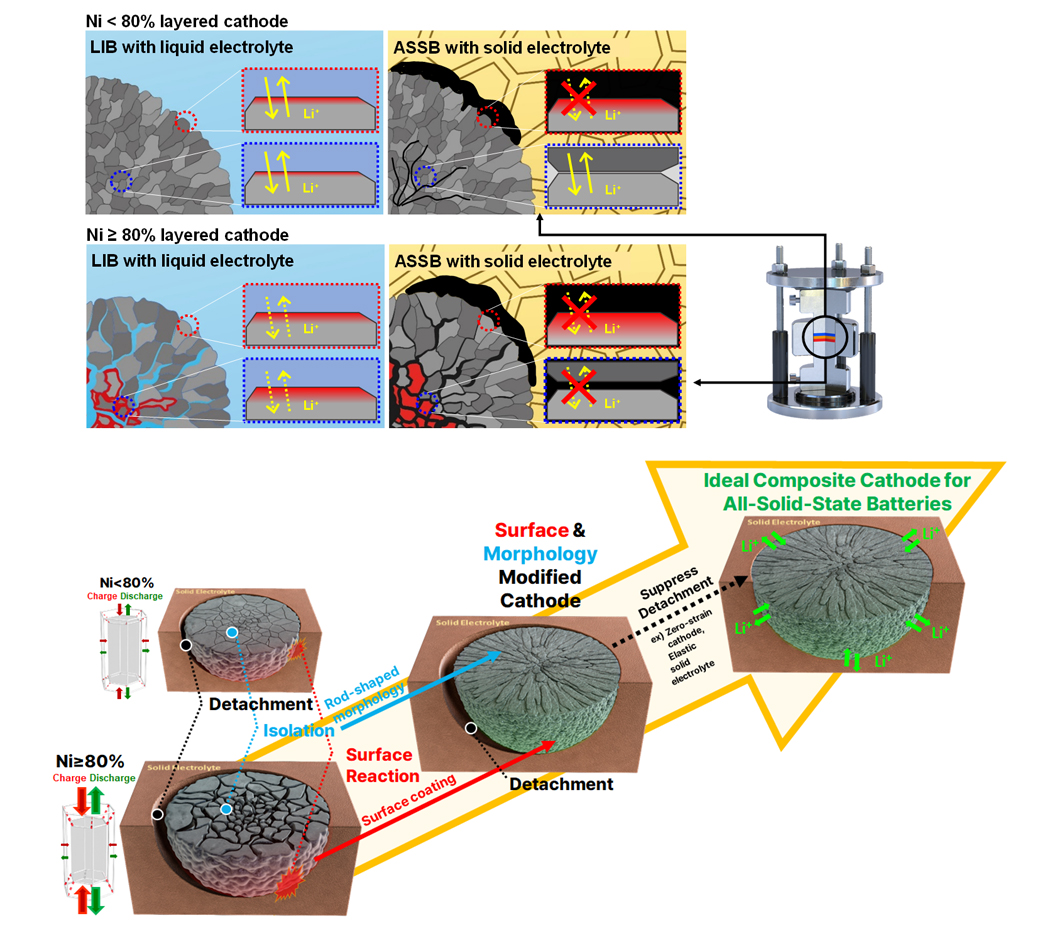

The commonly known causes of performance degradation in All-Solid-State battery are interfacial reaction problems between the particles. Unlike well-

studied liquid electrolytes mechanisms, that of solid electrolytes requires more research. We thoroughly research the difference between them to mitigate

the problem while maintaining high energy density and to define which cathode material suits best for All-Solid-State batteries.

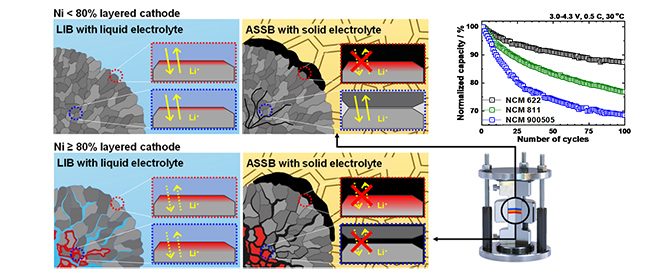

Investigating degradation mechanism

We demonstrate the trends of all-solid-state NCM with different Ni contents, that is, the clear correlation between capacity or cycling stability with Ni content.

Meanwhile, recent investigations on the microstructural evolution and design strategies of Ni-rich cathodes for advanced LIBs have caught our attention as a

possibly overlooked clue to solving the aforementioned puzzle in the ASSB field.

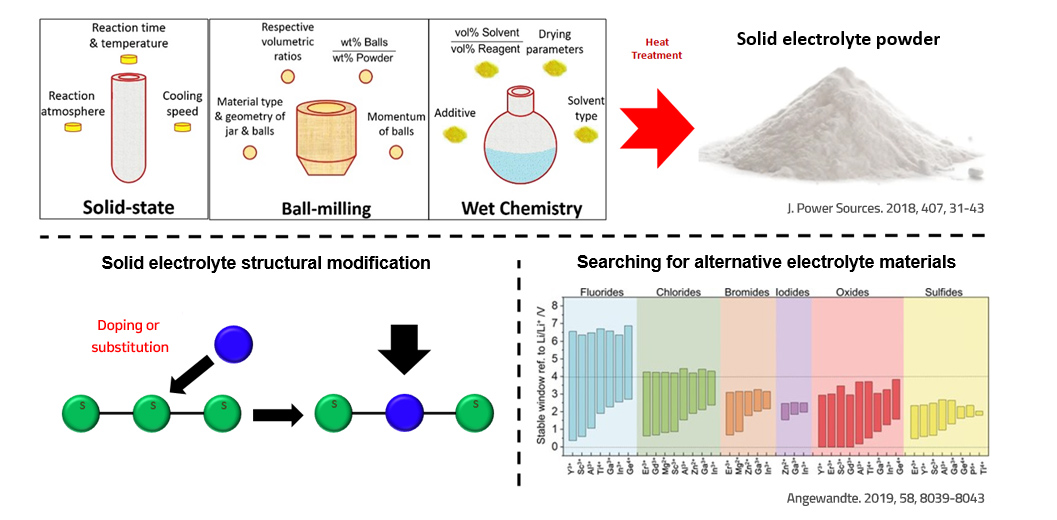

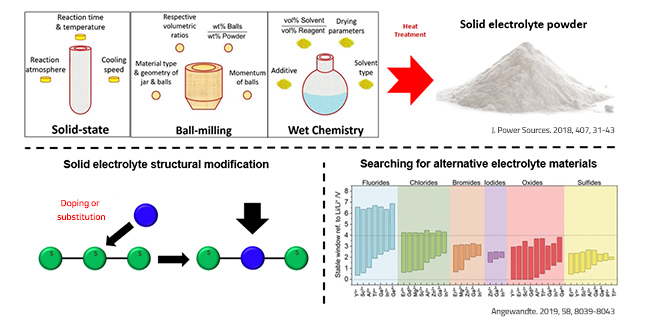

Solid Electrolyte Synthesis

The most fundamental material in the All-Solid-State Battery is a solid electrolyte, and synthesizing methods are being researched in our lab. We synthesize

sulfide solid electrolyte that has high ionic conductivity, but its electrochemical window is too narrow limiting its usage. Therefore, we modify sulfide solid

electrolytes by doping or substituting stable material to improve its stability. Or, a different type of solid electrolyte is synthesized that a has wide

electrochemical window with high ionic conductivity. Our final goal of solid electrolyte research is synthesizing the next-generation solid electrolyte for the

best conductivity with outstanding stability.

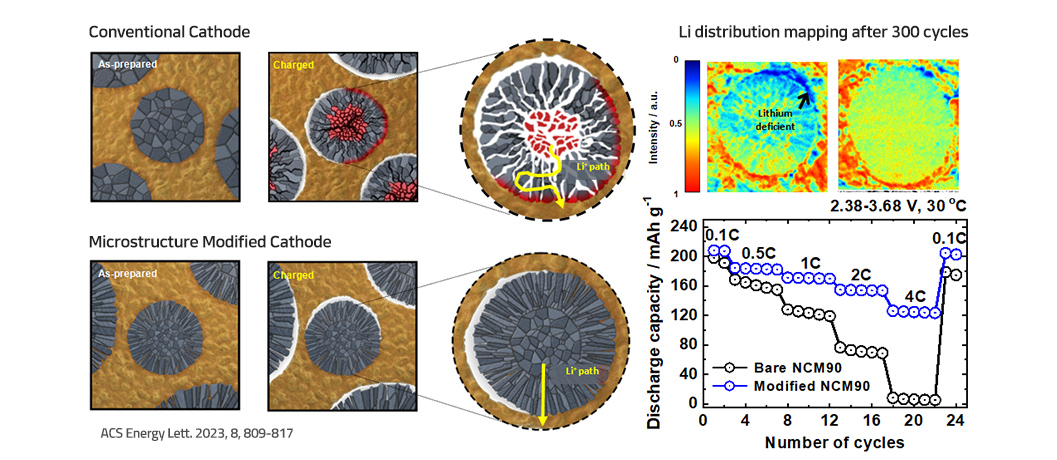

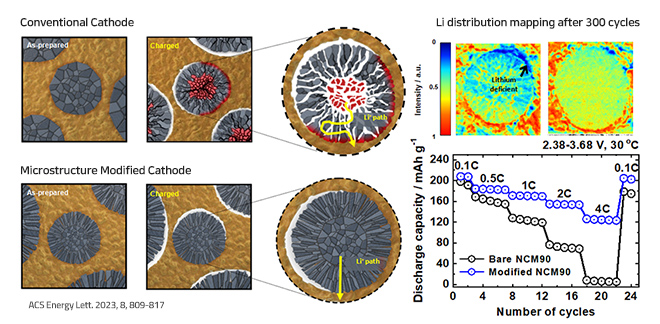

Microstructure Engineering

With microstructure tailoring on the cathode, the All-Solid-State Batteries can have high electrochemical performance with long cycle retention.

The long and radially straight particles from the core shorten the Li+ path and mitigate isolated particles. Our research further investigates the morphology

and design for mechanical advancement for the best cathode to apply in All-Solid-States Battery.

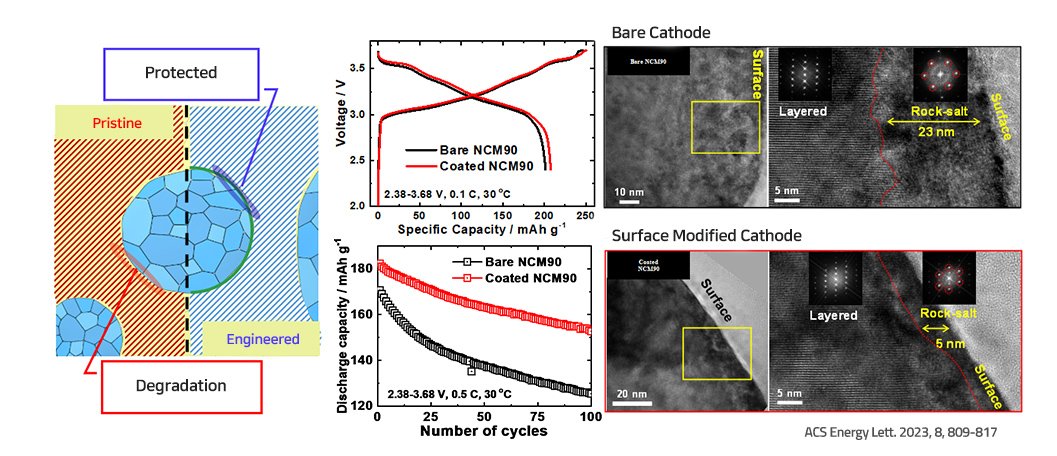

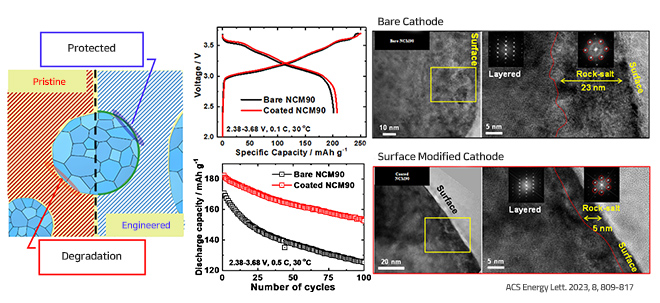

Interface Engineering

When the contacting surface area between solid electrolyte and cathode is degraded into electrochemically inactive material, the performance of battery

instantly fails. To mitigate the degradation, we thoroughly investigate the chemical reaction between the cathode and solid electrolyte to examine the

interface mechanism. With understanding of the mechanism, we engineer the surface of cathode particle to protect chemical degradation while maintaining

conductivity. We continue to enhance the interface engineering to protect the surface of cathode to bring out its full potential.

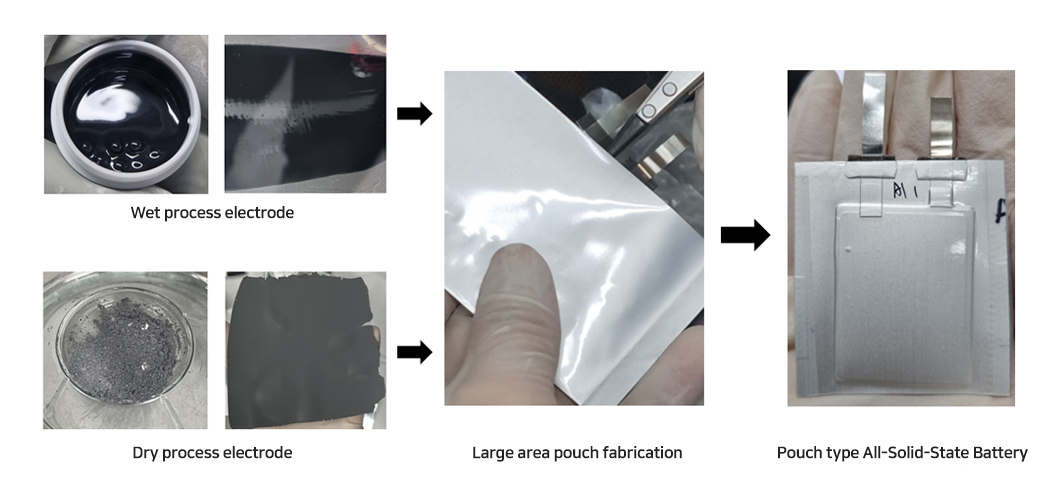

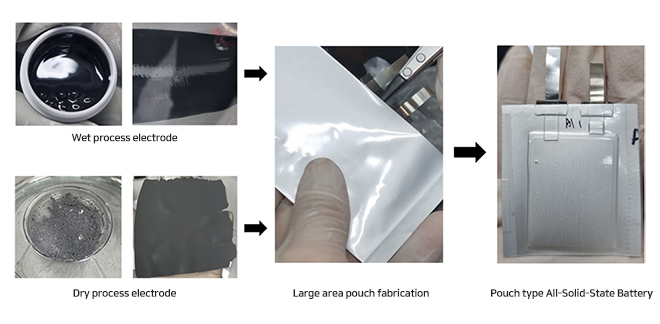

Large-area pouch cell

Most All-Solid-State battery labs electrochemically test their material in pelletized electrodes. However, it is merely lab scale application which is far different

than industrial application. For practical application, All-Solid-State batteries should be applied in pouch type cells. However, there are many differences

between pouch type batteries from pellet batteries, such as different constant pressure and thicknesses of electrodes. We research to overcome the

problems from the difference, so that All-Solid-State battery technology can be applied in our life.